The seemingly increasing conflict in the Red Sea region in 2024 has caused major disruptions to global shipping routes and supply chains. The industrial sector in Asia-Pacific (APAC) has been hit especially hard.

Port closures, naval blockades, and the threat of further military action have choked off key trade arteries. This has led to shipping delays, soaring freight rates, and shortages of raw materials and components.

A Vital Trade Artery Under Siege

The Red Sea is one of the world’s most dire maritime chokepoints at the moment, with an estimated 11% of global trade passing through its waters. It provides the shortest sea route between Europe and Asia via the Suez Canal.

But simmering geopolitical tensions in the region boiled over in early 2024 with a multinational conflict involving major Red Sea littoral states as well as outside powers. The result has been a virtual shutdown of commercial shipping through the area.

As of May 2024:

- Transit through the Suez Canal has dropped 80% from pre-crisis levels due to the security risks. Hundreds of ships are stuck waiting on either side.

- Attacks on multiple oil tankers and container ships have been reported, with tens of billions in cargo destroyed or held up. Insurance costs for vessels transiting the Red Sea have risen by 2,700% in some cases.

- At least two major Asia-Europe undersea data cables in the Red Sea have been severed by military action. This has disrupted digital communications and transactions.

These developments amount to a worst-case scenario that maritime analysts have long warned about. The crisis has effectively cut the world in two and severed the primary trade and data links between East and West.

The Red Sea Conflict Has Wide-Ranging Impacts

The repercussions are being felt across the global economy. Sadly, industrial firms in APAC are taking the brunt of the impact.

The region is deeply embedded in international manufacturing networks and depends heavily on the Red Sea corridor for inbound materials and outbound finished goods. Japan, South Korea, Taiwan, and Singapore all send approximately one-third of their total exports to Europe via the Suez Canal. China sends nearly two-thirds to Europe using this route.

Specific pain points for APAC industrials include:

- Shortages of much-needed commodities typically imported from or through the Red Sea region such as oil, iron ore, copper, and rare earth elements.

- Severe delays receiving industrial components and intermediate goods from Europe, North America, and elsewhere. Inventory levels have plunged while stockout rates have surged.

- Massive bottlenecks and added costs shipping finished products to Western markets. Freight rates for a 40′ container from Shanghai to Rotterdam have skyrocketed from roughly $1,000 pre-crisis to over $3,000 now.

- Lost sales and contract penalties due to inability to fulfill orders on time.

APAC industrial companies cannot simply wait for pre-crisis conditions to return. They must take decisive action to insulate their supply chains and operations from the protracted impacts.

How APAC Industrial Companies Can Build Resilience and Adaptability

How can APAC industrial players deal with this turbulent environment and ensure that their stock keeps rolling out and that their inventory keeps rolling in? By embracing strategies to build resilience while remaining agile, for example, by:

1. Diversifying trade routes

APAC industrials should reduce their reliance on the Red Sea passage by utilizing alternate Asia-Europe rail links and Arctic shipping lanes. The China-Europe freight train network, for example, saw record traffic in Q1 2024.

2. Reshoring and nearshoring

APAC industrials should also bring supply chains closer to home markets to shorten lead times and limit exposure to overseas disruptions.

3. Boosting inventories

APAC industrial must maintain higher safety stocks of important materials to cushion against volatility.

4. Investing in visibility

APAC industrials should implement real-time monitoring of shipments and potential supply chain risks. Resilinc’s EventWatch AI, for example, allows businesses to track over 100 million supply chain disruption sources across 200 countries.

5. Embracing substitution

APAC industrials should consider designing products to allow swapping in alternate materials and components if primary inputs are unavailable because of shortages caused by the Red Sea crisis.

6. Prioritizing agility

APAC industrial companies must structure procurement, manufacturing, and logistics for rapid pivots as conditions change. According to McKinsey, companies that implement more agile supply-chain practices achieved service levels seven percentage points higher and maintain inventory levels 23 days lower compared to their counterparts with less agile practices.

While adapting to the new reality requires investment, inaction is not an option. Supply chains optimized solely for cost and efficiency have shown their vulnerability. The key going forward is building resilient and reconfigurable networks that can bend without breaking.

Better Leadership is Part of the Answer

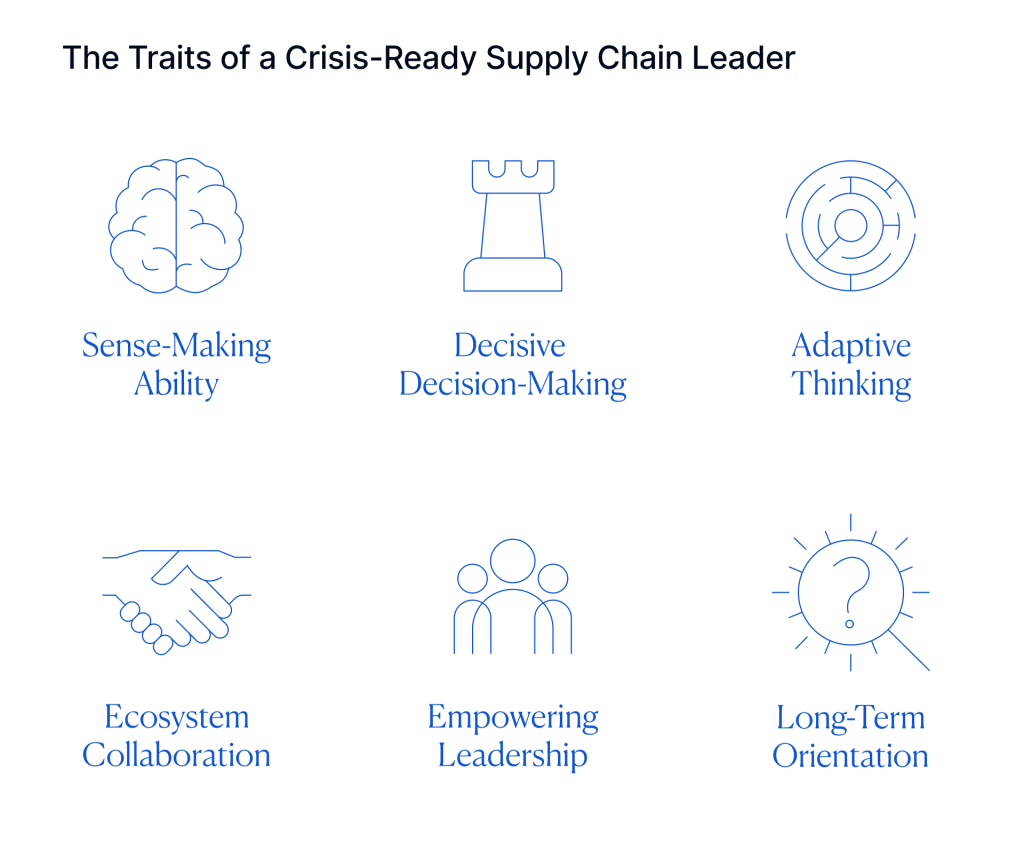

Adapting to this difficult new shipping environment requires more than just the right supply chain strategies (although they are certainly necessary, too). It also demands that APAC industrial executives develop key leadership skills and mindsets, namely:

1. Sense-making ability

Leaders must be able to quickly process complex and ambiguous information to diagnose root causes and effects when it comes to supply chain disruptions.

2. Decisive decision-making

Executives dealing with the industrial sector’s supply chain need to make difficult calls rapidly even with limited data and information, then clearly communicate the path forward.

3. Adaptive thinking

Fixed assumptions about suppliers, transportation, and markets no longer apply. Leaders must swiftly and quickly ideate new and novel solutions as conditions evolve.

4. Ecosystem collaboration

Coordinating closely with partners is important, but leaders must also engage stakeholders like regulators and investors around shared resilience priorities.

5. Empowering leadership

Command-and-control approaches are ineffective in fast-moving crises like these. Leaders must empower teams to make intelligent decisions, fail fast, and innovate on the fly.

6. Long-term orientation

Knee-jerk cost-cutting undermines resilience. Leaders must continue to invest strategically for the future while navigating short-term headwinds.

Leaders who have strong adaptive, collaborative, and decisive capabilities will be the ones who shepherd their organizations successfully through this and future crises.

Leaders who have strong adaptive, collaborative, and decisive capabilities will be the ones who shepherd their organizations successfully through this and future crises.

Stanton Chase can help your APAC industrial company identify and develop leadership talent with the skills needed. We offer a range of services, including executive search, succession planning, leadership assessment and development, board services, and executive onboarding, which can help you to ensure you have the right leaders leading your organization and that they are suitably empowered to succeed.

Light at the End of the Canal?

As for whether or when passage through the Red Sea and Suez will normalize, much uncertainty remains. Diplomatic efforts to broker a ceasefire between the different parties continue, but fundamental conflicts remain unresolved.

Even after hostilities subside, clearing backlogs and repairing damaged infrastructure will take additional months.

This means APAC industrial firms must continue adapting to a world where the Suez nexus can no longer be taken for granted and where the Red Sea remains a volatile area for transit. While building supply chain resilience is a complex undertaking, it is now an imperative.

Companies cannot predict the future, but they can prepare to better deal with whatever it may bring. Those who meet this challenge will be the winners in the next global industrial order.

About the Author

Frank Koh is a Partner at Stanton Chase Singapore and the APAC Industrial Regional Sector Leader. He brings over two decades of professional experience in providing comprehensive people solutions across China and the APAC region. With expertise in retained executive search and executive and career coaching, Frank has established trusted partnerships with clients in high-tech industries such as manufacturing, information technology, chemical, and life sciences. He holds an MBA from Preston University, a Graduate Diploma in HRM from the Singapore Institute of Human Resources, an Advanced Manufacturing Certificate 4.0 in Automation, and a Professional Certificate in Supply Chain Innovation. Frank is also a certified assessor of DISC profiling.

How Can We Help?

At Stanton Chase, we're more than just an executive search and leadership consulting firm. We're your partner in leadership.

Our approach is different. We believe in customized and personal executive search, executive assessment, board services, succession planning, and leadership onboarding support.

We believe in your potential to achieve greatness and we'll do everything we can to help you get there.

View All Services